How to Mend a Broken Process

What makes a good operational process and how to fix a bad one

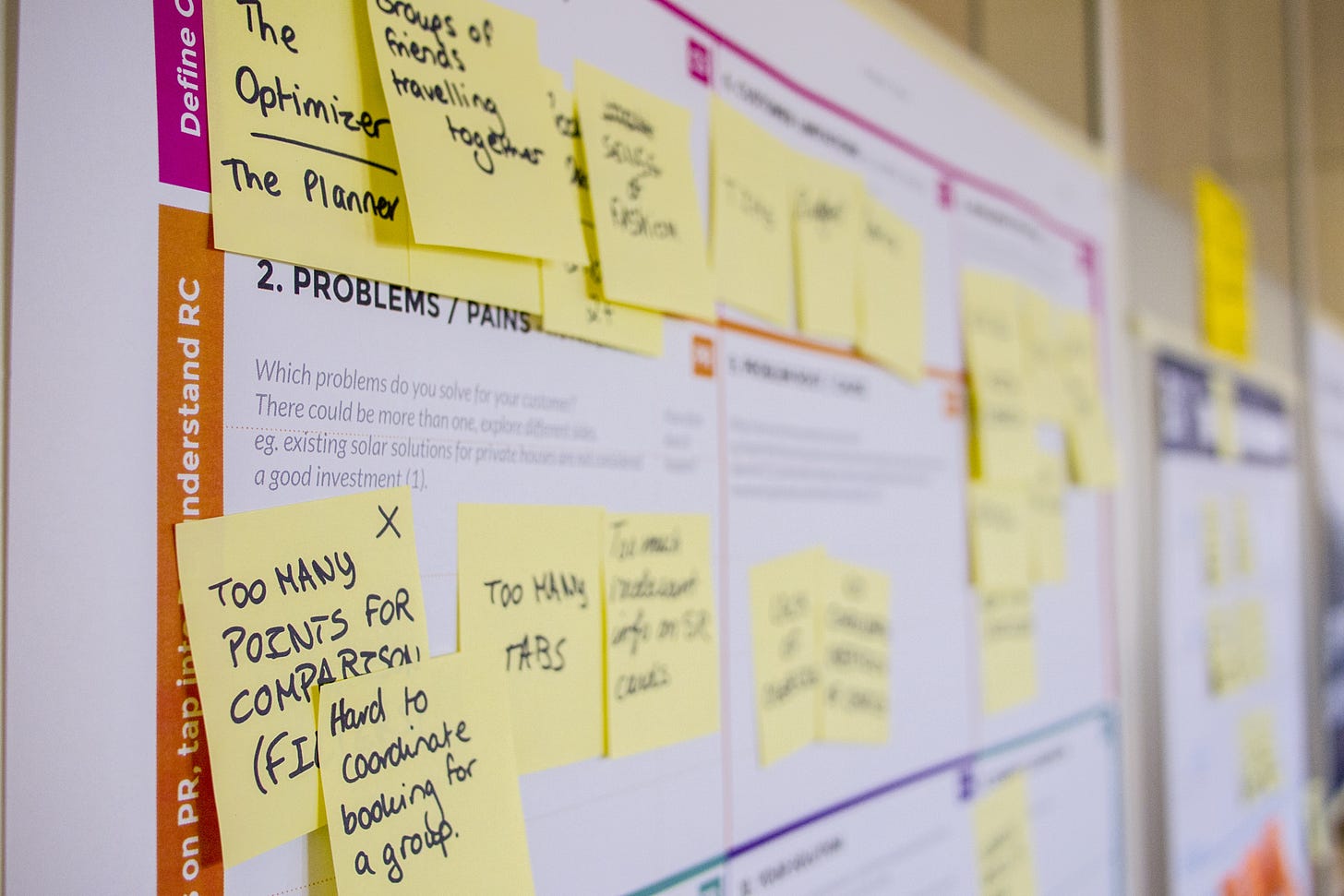

Photo by Daria Nepriakhina 🇺🇦 on Unsplash

The goal of any operations function is to fulfil the functions of the business and meet (or even exceed) the customer’s expectations with the optimum use of assets and resources. However good the strategy, it’s the execution that determines business success.

Processes are important to solopreneurs looking to delegate work all the way up to large multinationals. When scaling, then efficient business processes become critical. Broken processes break companies. Great operational processes provide competitive advantage and money in the door e.g. Amazon. Poor processes create dissatisfied customers, rework and waste and money out the door e.g. hey, you’ve all experienced loads of these.

What do Good Processes look like?

The easiest way to sort out a bad process is to know what good looks like in the first place. Here are some key characteristics of a good process.

Processes are fully documented and can be easily accessed and followed. Processes are documented and training material produced as standard. A larger firm might run an onboarding course for new joiners but smaller organisations can do likewise using software like Loom and video to record screenshots. Some firms utilise Trello Kanban boards, others send out an email per day.

Zero complaints and high customer satisfaction. Complaints are bad news. They tie up staff, require rework and they sap morale. Having a good complaints process to handle them is great but this is a process that should be gathering dust. Complaints tend to highlight break points but asking customers to rate their experience and point out any ho-hum moments can highlight areas for improvement. You’ll likely get a low rate of engagement if you’re doing ok but customers will tell you if they don’t like something.

Clear separation between process and content. Process means automated steps or routine tasks that can be easily delegated. Content is where the bulk of the value and differentiation is created or decisions are taken. Producing a podcast is a series of processes but only a few of those steps create the differentiated value i.e. choosing a guest, preparing for the recording and the recording itself are the key differentiators. Everything else is a repeatable process that can be done by many.

Ideally, anyone with some knowledge of the organisation should be able to follow the process even though they may not be able to work on the content e.g. the process by which a new medicine is regulated is easy to understand. The production of clinical evidence and the review of that is highly specialised.

One and Done i.e. the correct level of decision making. Ideally, tasks are ‘one and done’ i.e. once fully trained, there is no need to refer a decision or query to a supervisor or a back office function other than in exceptional circumstances e.g. I once worked in a call centre where a customer wanted to cancel her contract because a murder had taken place in the house! Unsurprisingly, no one had come across this before (and hopefully not since) but we took the opportunity to think about circumstances involving domestic violence and revise the guidance for staff. And yes we waived the contract.

Low variability in outcome and timing. Good processes are repeatable and consistent. This makes scaling up an operations centre easy because the skill sets required and the resources needed are well understood. Perhaps, more appropriate to recessionary times, it enables operations to scale back without affecting the customer experience. Conversely, high variability is an indication that the process isn’t working optimally. In one operation, we measured the time taken for each type of call and went to the voice recording to listen to those that were much shorter or longer than the average to identify best practice and some things that required fixing.

Processes are appropriate to changing business needs and customer base. As businesses grow, the customer base and market changes. ‘Educated’ early adopters are replaced by early/late majority customers (see Everett Rogers five personas for innovation adoption) who have different needs and characteristics. One organisation I worked with had a billing system that was designed for customers who paid their bills promptly. As the business grew, it needed to be redesigned to better handle the substantial number of customers who didn’t!

Processes are up to date. They are reviewed periodically e.g. annually and more specifically when there is a major change to the systems, new legislation or a change in strategy.

How to Fix a Broken Process?

Knowing what good is enables us to identify ones that are broken. However, most organisations tend to fixate quite obviously on ones that affect the customer experience vs internal processes, which are often suboptimal rather than completely broken. A suboptimal process increases cost, often involves rework and can be unrewarding for staff so they are well worth fixing. My recommended process is as follows

Map the current process (if not done so already) with the manager and a couple of team members.

Check the process by running it through end to end in the actual operation with people not involved in the first exercise

Devise some measurement around the current process and carry that out for a short period to get a baseline e.g. time taken to complete each stage

Highlight the pain areas i.e. parts where the process fails or the mapping isn’t correct

Devise new process and test using the same measurement

Document new procedure

Train everyone in the team in the new procedure then roll out

Make amendments if necessary

Don’t Forget the People Side

Designing good and hopefully bulletproof processes is not just an analytical exercise. It’s important not to forget the people involved and how they can make a huge difference to success or failure. It’s important to make sure that people’s interests and concerns are addressed.

Where processes are broken, then it’s not unusual to see the discussion become quite heated and not everyone may agree on what needs to be done. This may be an indicator of the need to think about the organisational structure and a target operating model (a future topic for another time) and/or bringing in some external help to provide an expert perspective.

Until Next Time

Pete